The measurement scenarios of R&D users are complex and changeable. There are not only temporary detection tasks, but also a lot of continuous sampling and testing work (such as trend analysis, reliability verification, destructive testing, etc.), and continuous sampling and testing often contain more attractive value. This makes the R&D users often face a dilemma when choosing a thermal imager: when choosing a hand-held thermal imager, they cannot cope with continuous sampling and testing; Online thermal imager is not flexible enough. FOTRIC 220s series thermal imager makes you no longer embarrassed: it is not only a hand-held thermal imager, but also an online thermal imager, which is more competent for long-term data sampling.

Small video of full radiation thermal image

Capture more data

The mobile phone can directly record 1000 frames of thermal image full radiation video, and capture the temperature change process in real time. Customized sampling rate (up to 5 frames/s), data can be collected automatically without PC.

Photo automatic naming

Data archiving is effortless

The mobile phone scans and automatically names the photos, saying goodbye to the tedious, inefficient and error of manual entry.

1T large file

Non disruptive data recording

The data collected in the long-term online mode is very large. FOTRIC 220s series thermal imager supporting software supports up to 1T single full radiation thermal image video recording, helping R&D users record complete data during the experiment.

Electronics industry

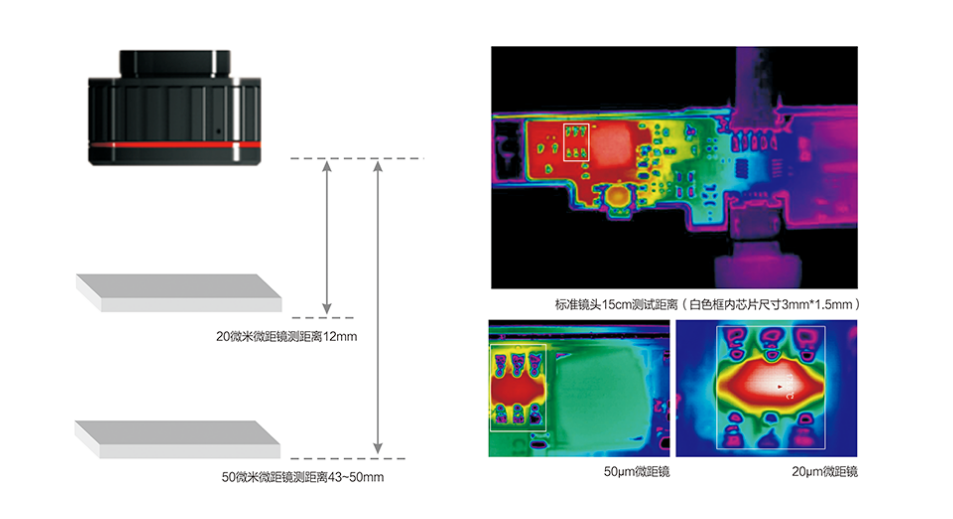

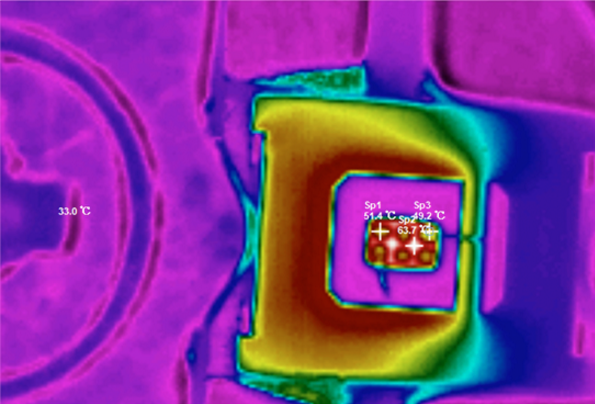

Internal temperature distribution test of unpacked chip

Test difficulty: most of the electronic heat distribution analysis can not be solved by a thermal image. It is necessary to see the process of temperature change and the temperature change of the whole experiment. Especially small and fine devices like chips.

Solution: For small targets such as chips, you can use Fotri c 226s with a 50 μ m macro lens, or even Fotri c 227s/228s with a 20 μ m macro lens for detection. Through the online analysis function of AnalyzIR, the temperature change process can be continuously detected, and can be analyzed arbitrarily after recording.